4 Wheel Electric Forklift Truck Cushion Tyre

LIGHT TO MEDIUM-DUTY APPLICATIONS

- Models

- E1.6-2.0XN

- Capacity

- 1600-2000kg

The highly durable and ultra reliable Hyster® E1.6-2.0XN series offers numerous advantages in quality and ergonomics, making it one of the most operator-friendly AC-powered lift trucks in the world. Setting the standard in electric lift trucks, it lowers overall operating costs and maximizes productivity. This is the workhorse you can count on day in and day out to get the job done.

- Superior serviceability

- Ergonomic design

- Low energy consumption

- Dependability

- Performance modes

AC-powered. Operator-friendly

The Hyster® E1.6-2.0XN series lowers your cost of operations by delivering increased productivity, lowered energy consumption, advanced dependability and reduced maintenance costs.

Using cutting-edge components and intelligent system design, the E1.6-2.0XN series operates with minimal downtime, and is assembled on a state-of-the-art assembly line utilizing the latest in manufacturing processes and techniques.

Superior serviceability

Ergonomic design

Low energy consumption

Dependability

Performance modes

The E1.6-2.0XN series utilises CANbus communications to simplify wiring and improve serviceability.

State-of-the-art on-board diagnostics reduce repair time and minimise expensive part-swapping.

A two-piece floor plate and side plates can be easily removed for unrestricted service access. The lift-out floor plate requires no tools for quick and easy daily operator checks.

Easy battery access is provided via the gas spring-assisted hood and quick release handle. The rear counterweight service cover is easily removed by loosening two screws.

The superior ergonomic design of the E1.6-2.0XN series means greater comfort for your operator. Enhanced ergonomics combined with customizable performance characteristics increase overall productivity and uptime.

• Easy-to-use 3-point entry design of operator compartment uses a molded hand grip and armrest/hip restraint to minimise muscle/joint strain.

• Seat Side Mechanical Levers are positioned for maximum comfort and offer an optional integrated thumb-actuated directional control switch.

• Adjustable steer column assures the right fit.

• Choice of 6 different seats enables a more customisable level of comfort.

• 12-inch steering wheel with integrated spinner knob reduces fatigue, provides more knee room, and goes lock-to-lock in just 4 turns.

• Optional auxiliary DC converter provides an automotive-style 12-volt outlet and an auxiliary power tap for customer installed accessories.

The standard AC traction and hydraulic motors set the standard in materials handling, significantly reducing time-consuming maintenance requirements.

The E1.6-2.0XN series operates with minimal downtime, and is assembled on a state-of-the-art assembly line utilizing the latest in manufacturing processes and techniques.

The standard AC traction and hydraulic motors set the standard in materials handling, significantly reducing time-consuming maintenance requirements.

The unitised design and welded steel construction of the frame provide better rigidity and excellent protection for the internal components.

The cast ductile iron steer axle with transverse, double-acting hydraulic cylinder, tapered roller spindle-support bearings and non-adjustable tie rods provide maximum durability with superior steering control and load handling.

Double-sealed electrical connectors provide a dust proof and waterproof connection to prevent contamination-related failures. Leak-free O-ring face seal fittings reduce leaks for enhanced reliability.

All vehicle systems are managed electronically to optimise performance, significantly increase overall reliability, and enhance diagnostic capabilities for maximum uptime.

Customizable performance that matches operator skill with individual performance needs enables the E1.6-2.0XN series to give maximum productivity throughout the entire shift.

Adjustment of customisable performance parameters to match your application needs is accessible via the multifunction display and technician password protection.

A significant increase in loaded travel speeds and acceleration rates beyond the standard setting is possible when the Extended Shift setting is turned off.

Our standard Extended Shift AC controller settings provide the optimum balance between performance needs and battery shift life.

| Model | Load Capacity | Load Centre | Lift Height | Turning Radius | AST (wide / long) | Battery Capacity | Weight |

|---|---|---|---|---|---|---|---|

| E1.6XN | 1600kg | 500mm | 5500mm | 1644mm | 3216 / 3404mm | 48V / 690Ah(V/Ah) | 3414kg |

| E1.8XN | 1800kg | 500mm | 5500mm | 1657mm | 3226 / 3417mm | 48V / 690Ah(V/Ah) | 3532kg |

| E2.0XN | 2000kg | 500mm | 5500mm | 1692mm | 3216 / 3452mm | 48V / 690Ah(V/Ah) | 3719kg |

OPERATOR ASSIST SOLUTION

FORKLIFT FLEET INSIGHTS & CONTROLS

Hyster Tracker forklift telemetry provides true wireless fleet management, equipping operations with actionable insights to drive fleet efficiency, improve operator performance, reduce carbon emissions and lower overall materials handling costs. Wireless monitoring, the base level of Hyster Tracker, comes standard on all A Series models.

POWER YOUR POSSIBILITIES

HYSTER POWER MATCH

Not all power is the same. Learn how a better-matched power source could make a difference in your operations.

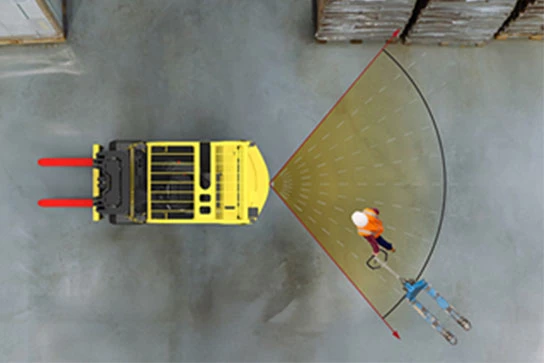

OPERATOR ASSIST SOLUTION

PEDESTRIAN AWARENESS ACTIVE ALERTS & INTERVENTIONS

Hyster Reaction pedestrian awareness active alerts and interventions are an optional tool to help support operators in looking out for those on foot around them. The camera system can be used for both indoor and outdoor applications, and it accurately identifies pedestrians at ranges up to 16 feet through a 110-degree field of view and provides your choice of automatic alerts to the forklift operator when a pedestrian is detected.

The truck is only part of the solution

Hyster knows that a tough truck, is even better when it comes with a strong partner to meet your unique needs.