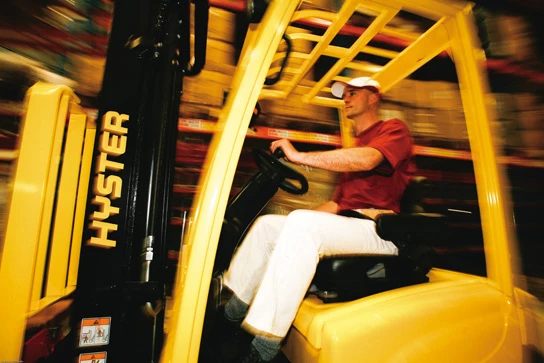

Handling in Explosive Environments

Manufacturing and logistics processes in petroleum, gas, industrial and agricultural industry segments often occur in the presence of explosive powders or vapours.

- Protect your people.

- Protect your plant.

- Protect your reputation.

Nearly all warehouse and counterbalance trucks can be converted to work in ATEX rated explosive environments.