SKU Proliferation

The seismic shift in 3PL warehousing means managing a huge volume of smaller orders and a tremendous number of SKUs.

How can you beat the SKU invasion?

- Optimise slotting for picking.

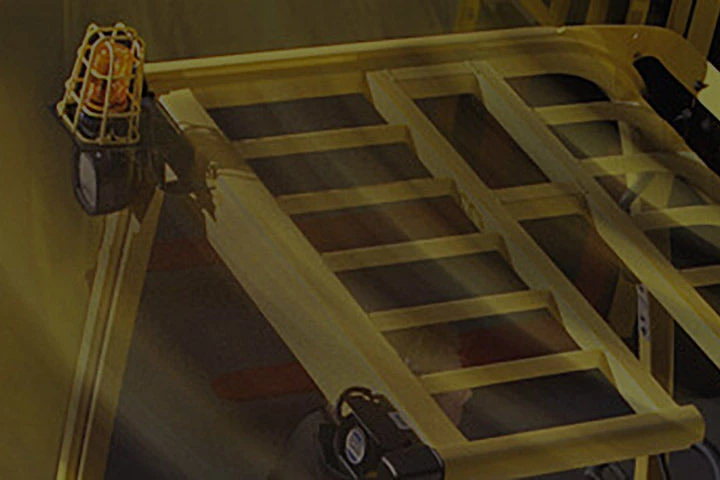

- Add carton live storage to accommodate more SKUs.

- Use multi level picking processes to increase pick locations.