RELIABLE AUTOMATED TUGGER

HYSTER ATLAS AUTOMATED TOW TRACTOR

- Models

- LO150TR

- Capacity

- 15000lbs

The Hyster Atlas™ automated tow tractor is built to handle horizontal load transportation in demanding manufacturing environments. Compatible with most cart styles and models, it’s a dependable, straightforward, affordable automated tugger for repetitive indoor towing and point-to-point moves, including:

- Sequencing in assembly operations

- Kitting separate items to be supplied as one unit

- Moving raw materials

- Transporting waste

- Replenishing stock and hauling materials

- Transporting product from one conveyor to another

AUTOMATED TUGGER AMPLIFIES WHAT YOUR CREW CAN DO

People are the backbone of your material handling operation, navigating mounting challenges and etching out efficiencies daily. The Hyster Atlas automated tugger deploys without custom code or software engineering, so your workers can do more with less.

- Straightforward setup. Just manually operate the automated tow tractor around your factory or facility and drop waypoints in the user-friendly portal.

- Independent navigation. The automated tow tractor builds its own map and tracks where it is using simultaneous localization and mapping (SLAM).

- Reliable 2D LiDAR. This autonomous tugger is equipped with a 2D LiDAR system that understands the truck’s position and direction of travel, even in complex factory environments.

- Built-in obstacle detection. Sensors along the bottom of the robotic tugger detect low-lying objects while a 3D camera system detects suspended objects in the travel route. The truck steadily slows to a stop until the obstruction moves or has been removed.

- Operator presence detection. Another 3D camera scans the operator compartment to prevent automated movement when an operator is present but has not switched the truck to manual mode.

Amplify what your crews can do with automated tuggers that don’t require constant babysitting. Charge, hitch, and unhitch without operator or supervisor intervention to keep your employees focused on more pressing priorities.

- Hands-free charging. This automated tugger charges itself, automatically returning to a charging station and wirelessly docking on its own so that your workers don’t have to stop what they’re doing to keep it powered up.

- Autonomous hitching. The available automated hitch and unhitch option allows the tow tractor to connect and disconnect carts between tows automatically, enabling your crew to focus on other challenges worthy of their skills and training.

Your operation has enough on its plate. You can’t be bogged down by disjointed integration, too many vendors in the mix, or long waits for help from halfway around the world. Hyster Atlas automated tuggers are standard, manual tow tractors outfitted with robotic technology, making life easier for your crew with familiar service and flexible operation.

- Local support. The trusted Hyster® dealer network has training, parts, and service covered.

- Familiar parts, more uptime. The automated tow tractor is manufactured with the same reliable parts as its manual counterpart for convenient service and support.

- Built for easy upkeep. Automation components like LiDAR and sensors are integrated separately so updates and maintenance don’t interfere with other components.

Use whatever cart you need. The automated tow tractor takes multiple hitch types and cart styles, so it can handle just about any horizontal load transport job you throw at it.

- Carts for all kinds of tasks. Flatbed, pallet, mother-daughter, shelf, and purpose-built carts cover a wide range of material handling workflows that an automated tugger can manage.

- All the hitch options you need. From multipurpose and ball hitches to automated hitch-unhitch connectors, facilities can easily pick the right fit — whether it’s a standard lunette connector, one that reduces noise or jarring of fragile loads, or a setup that minimizes operator involvement.

DOWNLOAD CARTS FLYER

| Model | Load Capacity | Turning Radius | Battery Capacity Voltage | Overall Width |

|---|---|---|---|---|

| LO150TR | 15000lbs | 60 | 24V / 525-600Ah | 40 |

Dealer network support

We would not be where we are today without one of the most professional dealer networks in the industry. We work hard to design and manufacture the best lift trucks, but it is our stellar dealers that bring it all together for you.

DEALERS HELP AT EVERY STEP OF THE PROCESS

- Understanding your specific lift truck applications

- Recommending special features to improve your productivity

- Configuring the proper quotation

- Helping with financing options when required

- Prepping your truck for delivery after it leaves our factory

- Arranging for operator training

- Providing planned maintenance on your trucks

- Supporting National Accounts management

- Providing fleet management services, if needed

- Providing emergency service and parts

- Providing rental trucks at short notice

- Helping determine exactly when to purchase new lift trucks

The GSA creates a centralized location for the federal government, offering products, services, and facilities needed for federal agencies to serve the public. As a GSA certified company, Hyster supports the GSA’s mission to provide innovative solutions for federal agencies with cost-effective and high-quality products. You can also find more information on the General Services Administration at www.gsaadvantage.gov

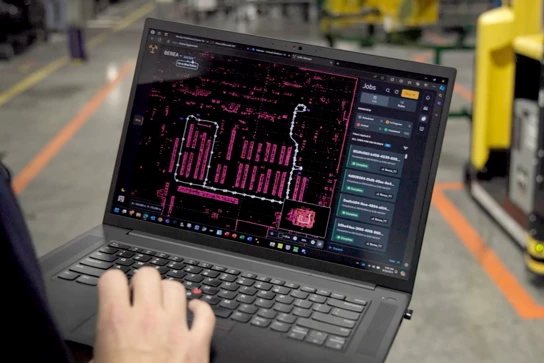

DRAG-AND-DROP PORTAL

EASY-TO-USE AUTOMATION MANAGEMENT SOFTWARE

What once took days or weeks of coding can be done with a few taps. The user-friendly, cloud-based Hyster Atlas drag-and-drop portal can get automated lift trucks running in your facility in as little as a day. Adjust routes and manage fleets without pricey programming or software engineering specialists. It offers:

- Intuitive mapping

- Easy, real-time updates

- Simplified fleet management

- Straightforward traffic management

ADDITIONAL RESOURCES

THE TRUCK IS ONLY PART OF THE SOLUTION

Hyster knows that a tough truck is even better when it comes with a strong partner to meet your unique needs.