INTERNAL COMBUSTION ENGINE PNEUMATIC TIRE

INTERNAL COMBUSTION ENGINE PNEUMATIC TIRE

- Models

- H30-40A

- Capacity

- 1360-1810kg

Start with a singular base configuration, then add only what you need to best suit your operational needs — no more, no less. By designing a completely unique forklift, you get the comfort and performance you desire, plus the cost benefit of only paying for what your operators and operation need in order to perform optimally.

- Dynamic Stability System (DSS)

- Operator-Centric Design

- Heavy-Duty Components

- Operator Assist Systems

THE RIGHT OPTIONS FOR YOUR OPERATION

The maintenance-free Dynamic Stability System DSS solution reduces the likelihood of tip overs and reminds forklift operators of safe operating practices by monitoring operating conditions and automatically limiting truck functionality when potentially unsafe conditions are detected.*

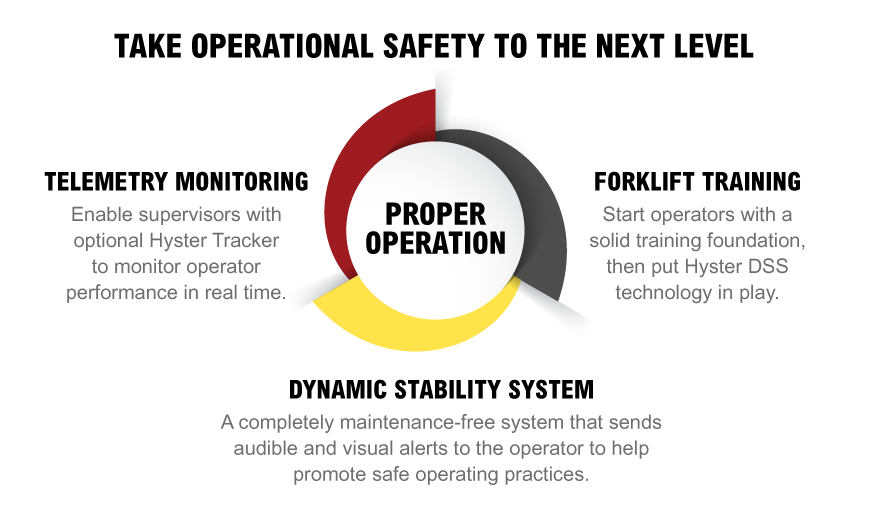

To take your operational safety to the next level, pair DSS with a professional grade forklift training program and optional Hyster Tracker telematics. When you start operators with a solid training foundation, put Hyster DSS technology in play, and enable supervisors with Hyster Tracker to monitor operator performance in real time, you have the right tools to improve safety in your work environment.

- A large step and grab handle, contoured hood and flip up armrests help make it easy for the operator to get in and out of the truck.

- Generous compartment space offers the operator an opportunity to find a comfortable position and stretch their legs.

- An optional clear glass roof and large mast opening help provide excellent visibility.

- Utilizes a heavy-duty EPA-certified Yanmar 2.2L LPG engine designed with extended preventive maintenance service intervals for continuous, heavy use.

- Engineered with a reliable, aluminum transmission and robust steer axle with tapered roller bearings to help minimize downtime and simplify service.

- Rear-Facing Camera with corresponding LCD rear view display

- Spotlight and pedestrian awareness light options, mounting positions, colors and control methods

- Optional shelf height selector with one-touch activation

- Slim, LED, mast mounted work lights

- Optional LPG tank bracket interlock

| Model | Load Capacity | Load Centre | Lift Height | Turning Radius | Overall Width | Engine | Transmission |

|---|---|---|---|---|---|---|---|

| H30A | 1360kg | 610mm | 5640mm | 2053mm | 1070mm | Yanmar 2.2L LPG | Electric powershift |

| H35A | 1590kg | 610mm | 5640mm | 2066mm | 1070mm | Yanmar 2.2L LPG | Electric powershift |

| H40AS | 1810kg | 610mm | 5640mm | 2085mm | 1070mm | Yanmar 2.2L LPG | Electric powershift |

We would not be where we are today without one of the most professional dealer networks in the industry. We work hard to design and manufacture the best lift trucks, but it is our stellar dealers that bring it all together for you.

Dealers help at every step of the process

- Understanding your specific lift truck applications

- Recommending special features to improve your productivity

- Configuring the proper quotation

- Helping with financing options when required

- Prepping your truck for delivery after it leaves our factory

- Arranging for operator training

- Providing planned maintenance on your trucks

- Supporting National Accounts management

- Providing fleet management services, if needed

- Providing emergency service and parts

- Providing rental trucks at short notice

- Helping determine exactly when to purchase new lift trucks

DON’T SETTLE FOR LESS THAN DSS - DYNAMIC STABILITY SYSTEM

Forklift safety is critical in materials handling operations. That’s why we engineered the Hyster® Dynamic Stability System (DSS) as an option on the A Series model . The innovative system helps support confidence and promote safe operating practices for forklift operators. Click through each aspect to learn more.

Lateral forklift stability system

Reduces lift truck lean in turns, helping to improve lateral stability. The innovative steer axle design allows for superior travel over uneven surfaces. The system is 100% maintenance free, with no controller, sensors or wiring.

High-lift traction control

Limits truck speed when the carriage is raised above the height threshold. Operator will receive a visual indicator on the truck display and an audible alert.

High-lift tilt control

Limits tilt speed and forward tilt range when the carriage is raised above the height threshold while carrying a load. Operator will receive a visual indicator on the lift truck display and an audible alert.

Corner control

Dynamically limits speed when driving around corners, based on how tightly the truck is turning. Operator will receive a visual indicator on the forklift display and an audible alert.

WIRELESS ASSET MANAGEMENT

HYSTER TRACKER

Hyster Tracker provides true wireless fleet management, drives fleet efficiency, improves operator performance, reduces your carbon footprint and lowers your overall material handling costs.