Wide forklift mast for exceptional visibility

Forklift safety is key; dynamic stability is standard

- Models

- H40-70A

- Capacity

- 4000-7000lbs

Start with a singular base configuration, then add only what you need to best suit your operational needs — no more, no less. By designing a completely unique internal combustion forklift, you get the comfort and performance you desire, plus the cost benefit of only paying for what your operators and operation need in order to perform optimally.

- Dynamic Stability System (DSS)

- Operator-Centric Design

- Exceptional Forklift Visibility

- Keep Costs Under Control

- Operator Assistance Systems

THE RIGHT OPTIONS FOR YOUR PNEUMATIC FORKLIFT

The maintenance-free Dynamic Stability System DSS solution reduces the likelihood of tip overs and reminds forklift operators of safe operating practices by monitoring operating conditions and automatically limiting truck functionality when potentially unsafe conditions are detected.*

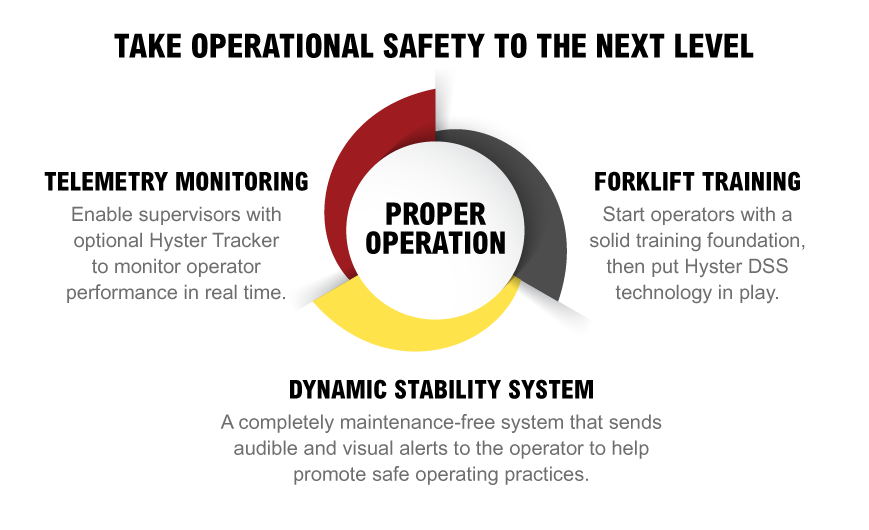

To take your operational safety to the next level, pair DSS with a professional grade forklift training program and optional Hyster Tracker telematics. When you start operators with a solid training foundation, put Hyster DSS technology in play, and enable supervisors with Hyster Tracker to monitor operator performance in real time, you have the right tools to improve safety in your work environment.

* While lift truck systems support safe operation and help minimize the potential for tip overs, proper operation of the lift truck and 100% full-time utilization of the truck’s seat belt are the primary and best means of keeping the truck and operator upright and safe. Refer to the operator and service manuals for proper operation and maintenance.

- Seat and step are close together, making entry and exit easier

- Large step provides a greater foothold for the forklift operator

- Flip-up armrests are included with optional suspension seats

- Large floor space

- Dynamic seat adjustment provides up to 25% more forward & backward seat flexibility than the leading competitor*

- Greater head and shoulder clearance than the leading competitor

- Foot-activated, hand-released parking brake is designed to tuck out of the way when applied, enabling unobstructed entry and exit

- Standard, full-color touch-screen display

* Compared to Toyota 8 Series 8FGU25 model. Competitive comparison data validated through internal testing.

- A low dash and a wide forklift mast give the operator excellent visibility of the fork tips

- High-strength laminated glass roof provides an unobstructed upward view

- The wide viewing window through the mast enhances visibility of forks and load

The robust Yanmar industrial engine is designed to create increased service intervals. Other standard components such as tapered roller bearings, O-ring face seals, and double-sealed electrical connectors require less frequent maintenance. Optional components are available to further reduce maintenance time and cost:

- On-demand cooling with reversing fan

- On-demand hydraulic system

- Wet disc brakes

- Advanced Duramatch™ electronic transmission

- Rear-Facing Camera with corresponding LCD rear view display

- Spotlight and pedestrian awareness light options, mounting positions, colors and control methods

- Optional shelf height selector with one-touch activation

- Slim, LED, mast mounted work lights

- Optional LPG tank bracket interlock

| Model | Load Capacity | Load Center | Lift Height | Turning Radius | Overall Width | Weight | Engine Type | Transmission |

|---|---|---|---|---|---|---|---|---|

| H40A | 4000lbs | 24in | 200 | 86.3 | 45.7 / 50.4 | 7600 | Yanmar 2.1L Diesel / Yanmar 2.2L LPG | Powershift 1-speed / Duramatch |

| H50A | 5000lbs | 24in | 200 | 89.1 | 45.7 / 50.4 | 8430 | Yanmar 2.1L Diesel / Yanmar 2.2L LPG | Powershift 1-speed / Duramatch |

| H60A | 6000lbs | 24in | 200 | 93.5 | 46.7 / 53.3 | 9890 | Yanmar 2.1L Diesel / Yanmar 2.2L LPG | Powershift 1-speed / Duramatch |

| H70A | 7000lbs | 24in | 200 | 96.4 | 46.7 / 53.3 | 10680 | Yanmar 2.1L Diesel / Yanmar 2.2L LPG | Powershift 1-speed / Duramatch |

We would not be where we are today without one of the most professional dealer networks in the industry. We work hard to design and manufacture the best lift trucks, but it is our stellar dealers that bring it all together for you.

Dealers help at every step of the process

- Understanding your specific lift truck applications

- Recommending special features to improve your productivity

- Configuring the proper quotation

- Helping with financing options when required

- Prepping your truck for delivery after it leaves our factory

- Arranging for operator training

- Providing planned maintenance on your trucks

- Supporting National Accounts management

- Providing fleet management services, if needed

- Providing emergency service and parts

- Providing rental trucks at short notice

- Helping determine exactly when to purchase new lift trucks

75% LESS PLANNED MAINTENANCE FOR $24,000+ IN SAVINGS

Differences in service frequency, parts pricing and fluid content stack up to serious savings compared to a leading competitive model.

Lifetime planned maintenance tasks & service costs over 10,000 hours of use

DON’T SETTLE FOR LESS THAN DSS - DYNAMIC STABILITY SYSTEM

Forklift safety is critical in the materials handling industry. That’s why we’ve engineered the Hyster® Dynamic Stability System (DSS) into every A Series model. The innovative system helps support confidence and promote safe operating practices for forklift operators. Click through each aspect to learn more.

Lateral forklift stability system

Reduces lift truck lean in turns, helping to improve lateral stability. The innovative steer axle design allows for superior travel over uneven surfaces. The system is 100% maintenance free, with no controller, sensors or wiring.

High-lift traction control

Limits truck speed when the carriage is raised above the height threshold. Operator will receive a visual indicator on the truck display and an audible alert.

High-lift tilt control

Limits tilt speed and forward tilt range when the carriage is raised above the height threshold while carrying a load. Operator will receive a visual indicator on the lift truck display and an audible alert.

Corner control

Dynamically limits speed when driving around corners, based on how tightly the truck is turning. Operator will receive a visual indicator on the forklift display and an audible alert.

Thought Leadership

Discover more about the A Series

WIRELESS ASSET MANAGEMENT

HYSTER TRACKER

Hyster Tracker provides true wireless fleet management, can drive fleet efficiency, improves operator performance, reduces your carbon footprint and lowers your overall material handling costs.

The truck is only part of the solution

Hyster knows that a tough truck, is even better when it comes with a strong partner to meet your unique needs.